Mop Making Machine – Manual

Mops composed of cotton, non-woven or synthetic material are assembled with this machine.This is a simple machine for producing mops of various sizes and forms. This Machine can build mops with plastic or metal sockets and staples from cotton yarns, spun-lace, and non-woven material spools. The mop is moved towards the cutting and unloading area once it has been built. This is a manually loaded, and the machine operator manually feeds the machine with sockets and staples (one each cycle) before starting the assembly cycle. It can mop twice as many floors per hour.

Manual Mop Machine

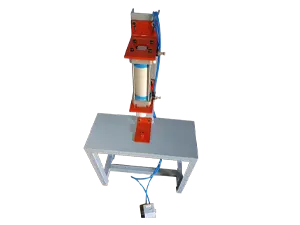

Pneumatic Mop Press

Mop Pattern Stitching Machine

Mop Making Machine – Semi Automatic

Semi-automatic machine for assembling cotton, non-woven, or synthetic mopsThis is a simple machine for producing mops of various sizes and forms. It can build mops with plastic or metal sockets and staples from cotton yarns, spun-lace, and non-woven material spools. The mop is moved towards the cutting and unloading area once it has been built. It is manually loaded, the machine operator manually feeds the machine with sockets and staples (one each cycle), and the assembly cycle is enabled.

Mop Making Machine – Fully Automatic

Fully Automatic Machine For Making MopsThis machine produces large quantities of high-quality industrial mops. It is a completely automated machine that performs all of the stages required to manufacture a finished narrow-band mop, including feeding the material, constructing the mop, and distributing the finished product. The machine may be operated by a single person. Machine feeds the mop material and the headband (2 synthetic material strips), then stitches the headband strips and mop material together with a multi-needle sewing machine.

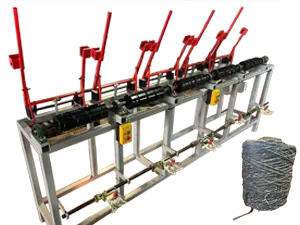

Automatic Loop End Mop Making Machine

Loop End mop making machine is capable of manufacturing mops that have 3 sidebelts, instead of the common cut-end cotton strand mops. This mop machine is used to make the mircrofiber mop material.

Twist mop is fed by mircofiber material (or similar materials), positioned on 4 sets of sewing machine. The machine winds the strands forming loops and then puts them together forming a hank. Then it thorught it out from the sewing machines in order to form the finished mop. And the worker should stand there for cutting the sideblet of mop .

Wet And Dry Mop Making Machine

Wet and Dry mop making machine is capable of manufacturing mops that have 4 sidebelts, instead of the common cut-end cotton strand mops. This mop machine is used to make the mircrofiber mop material is automatically machine for household mop industry.

Twist mop is fed by mircofiber material (or similar materials), positioned on 4 sets of sewing machine . The machine winds the strands forming loops and then puts them together forming a hank. Then it thorught it out from the sewing machines in order to form the finished mop. And the worker should stand there for cutting the sidebelt of mop .

Mop Pipes / Rods

Mops composed of cotton, non-woven or synthetic material are assembled with this machine.Our Mop Rods / Mop Pipes are produced using quality approved material and the latest technology with the set market standards. Together with this, our products are understood for their features like easy to use, great performance, strong built, and long service life.

Rotary Indexion Table( 6 Stage )

Rotary tables are used for precision metalworking. They are usually made with a solid base that can be attached to another fixture. The table is a disk that rotates freely or with the help of a worm gear (crank). A rotary table is a disk-shaped metallurgical device used in the past to gain workpiece positioning. It allows a metalworker to cut or drill a workpiece at precise intervals around a fixed vertical or horizontal axis.

A turntable can be controlled manually or numerically by a computer. Certain types of rotary tables are designed for use with index plates or special operations index plates. A rotary table used in conjunction with one of these mounting plates is typically referred to as a dividing or dividing head.

The turntable device usually has a solid base that can be attached to a separate fixture or table with clamps. This device is basically a rotating disk that holds the workpiece in place while cutting or drilling. The disc portion of a rotary table can be freely rotated for indexing operations or rotated by an attached control arm known as a worm wheel. Stages used in high precision operations are typically rotated with a duplex worm gear to take up backlash. Rotary tables used in automated metalworking processes are rotated by computer controlled machines. Rotary tables are most commonly placed in a flat position with the's table axis vertically aligned. They are sometimes assembled with the spindle horizontally aligned so that a tailstock can be used to support the free end of the workpiece.

When this device is attached to a sub-table, the workpiece can be centered on the axis of the rotary table, which is then centered on the axis of the cutting tool. In this configuration, the rotary table, sub-table, and cutting tool axes are coaxial to facilitate concentric cutting operations. This configuration also allows the sub-table to be offset to drill equally spaced holes in a workpiece.

Special Purpose Machines

Special Purpose machines are an advanced type of programmed and automated types of equipment designed according to the requirements of the clients. There have been many innovative quests to make excellent special purpose machines, in order to maximize productivity. Automation and technological advancements have drastically changed the manufacturing industry. One such aspect is Special Purpose Machine (SPM) design. As SPM is not created on standard manufacturing programs, immaculate design is crucial to ensure product performance and safety.

Automatic Tapping Machine

Fiber Laser Marker Machine

Automatic Metal Grinding Machine

Scissors Lift

Injection Moulding Machine

Robotic Pick and Place Technology

Mobile Phone Assembly Line

Motorised Cutting Table 42inch

Winding Machines

We are one of the most trusted names in the industry engaged in serving our esteemed clients with an exclusive range of Cheese Winder Machine. These machines are designed with precision in accordance with the industrial specifications that ensures reliability. Our clients can avail these machines in different grades and dimensions that suits best with their demands and requirements.

Automatic Jumbo Winding Machine

Capacity : 25 kg to 40 kg Single Bobbin

Cheese Winder Machine

Jumbo Winding Machine

Line Assembly Products

A belt conveyor is a system designed to transport or move physical items like materials, goods, even people from one point to another. Unlike other conveying means that employ chains, spirals, hydraulics, etc., belt conveyors will move the items using a belt. A conveyor system is used in many industries as a standard piece of mechanical handling equipment to move goods, products, raw goods, and other materials from one location to another, usually in the same area or building.